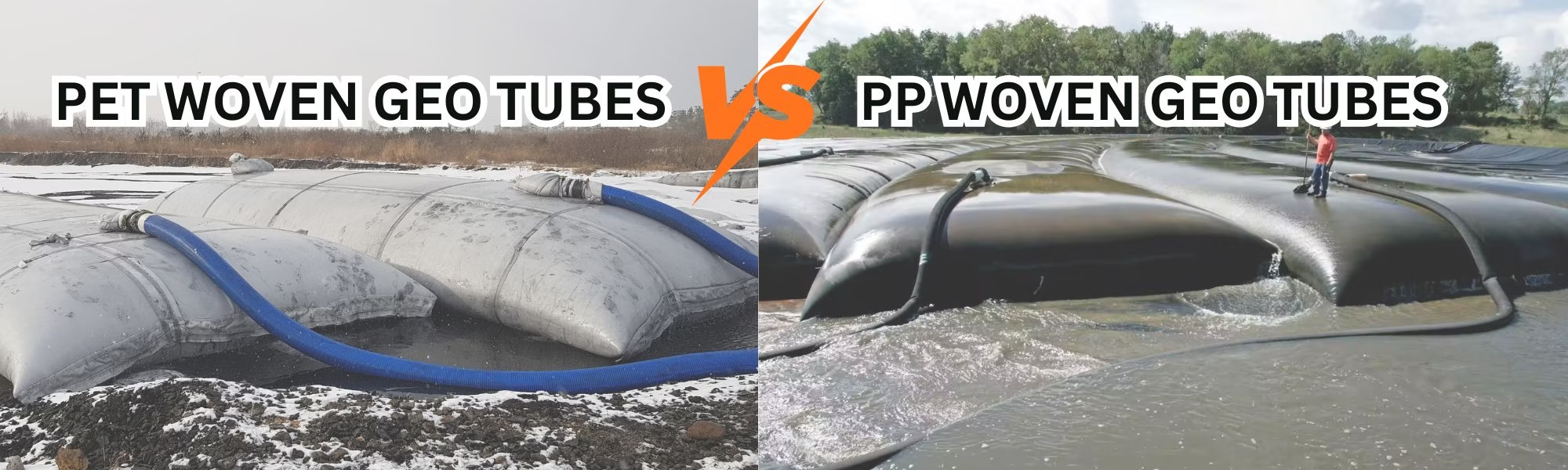

PP Woven vs PET Woven Geo Tubes for Marine Applications: An Engineering Perspective

In coastal and marine engineering projects, Geo Tubes are no longer considered temporary solutions. They are structural systems expected to perform reliably under high hydraulic loads, aggressive wave action, abrasion, and long-term exposure to UV radiation and saltwater.

One of the most common questions raised during design and procurement is:

Why do most marine Geo Tube specifications prefer PET woven geotextiles over PP woven geotextiles, even though PP is cheaper and widely available?

This article explains the answer from a performance-based engineering perspective, not a marketing one.

Understanding the Role of the Geo Tube Fabric

A Geo Tube fabric is not merely a filtration layer. In marine environments, it functions as a load-bearing membrane that must:

- Withstand high internal filling pressures

- Maintain dimensional stability after dewatering

- Resist puncture and abrasion from sand, shells, and debris

- Transfer loads safely through seams

- Perform reliably for many years under UV exposure and cyclic wave loading

Material selection is therefore a critical engineering decision.

1. Dimensional Stability and Creep – The Decisive Factor

One of the most important performance differences between PP and PET is creep behavior.

- PP woven geotextiles exhibit relatively high creep under sustained tensile load. Over time, this leads to elongation, loss of shape, uneven load distribution, and overstressing of seams.

- PET woven geotextiles offer excellent creep resistance, maintaining geometry under constant load and ensuring uniform stress distribution along the tube body and seams.

In marine Geo Tubes, creep is not a cosmetic issue, it is a structural failure mechanism. Loss of dimensional stability is one of the primary causes of long-term Geo Tube failure.

2. Seam Reliability – Where Most Failures Occur

In real-world installations, Geo Tubes rarely fail in the middle of the fabric. They fail at seams.

PP fibres have a lower melting point and are softer. During high-speed industrial sewing, local heat and friction can weaken yarns around needle perforations. PP fibres are also smoother, resulting in lower stitch-holding capacity.

As a result:

- Typical seam efficiency for PP woven fabrics: 55–70%

- Typical seam efficiency for PET woven fabrics: 80–95%

For marine Geo Tubes, where seams carry extremely high tensile loads during filling and service, PET provides a significantly higher safety margin.

3. Puncture and Abrasion Resistance in the Surf Zone

Marine Geo Tubes are continuously exposed to:

- Coarse sand

- Shell fragments

- Coral rubble

- Repeated wave-induced movement

Compared to PP:

- PET fibres are harder and more abrasion-resistant

- PET woven fabrics typically achieve 20–40% higher puncture resistance for the same tensile strength class

This difference becomes critical in surf zones and nearshore installations, where abrasion is continuous and unavoidable.

4. Permeability and Filtration Stability During Filling

Both PP and PET woven fabrics can be engineered to meet filtration and permeability requirements. However, under high filling pressures:

- PP woven fabrics tend to elongate, increasing the apparent opening size (AOS)

- PET woven fabrics maintain aperture stability, allowing controlled dewatering without excessive soil loss

Predictable dewatering is essential to:

- Achieve the intended design geometry

- Prevent sand loss during filling

- Avoid post-installation settlement and deformation

5. UV Resistance and Long-Term Service Life

In tropical marine environments:

- PP can lose 30–50% of its tensile strength within 12 months if not heavily UV-stabilized

- PET exhibits significantly better UV resistance, with much lower long-term strength loss

For this reason:

- PP woven Geo Tubes are generally limited to temporary or inland applications

- PET woven Geo Tubes are specified for permanent coastal protection works, with design lives of 10–25 years or more

6. Cost Versus Risk – The Real Comparison

Although PP woven fabrics may offer lower initial material costs, the evaluation should not stop there.

A single Geo Tube failure can lead to:

- Emergency replacement works

- Significant project delays

- Environmental damage

- Contractual disputes and reputational risk

In most marine projects, the cost of failure far exceeds the price difference between PP and PET fabrics.

Final Engineering Conclusion

PP woven geotextiles are not inferior materials. They perform well in many temporary, inland, and low-load applications.

However, for marine Geo Tubes subjected to sustained loads, wave action, abrasion, and long service life requirements, PET woven geotextiles consistently outperform PP by offering:

- Superior dimensional stability and creep resistance

- Higher seam reliability

- Better puncture and abrasion resistance

- Predictable filtration performance during filling

- Longer service life in aggressive tropical marine environments

This is why PET woven geotextiles remain the material of choice for serious marine and coastal Geo Tube applications worldwide.